Aluminum strip, can be divided into pure aluminum strip, transformer aluminum strip, super hard aluminum strip, all soft aluminum strip, semi-hard aluminum strip, rust-proof aluminum strip. Itis pure aluminum or aluminum casting coil, hot rolled aluminum coil, and is produced with cold rolling machine into different thickness and width, and then cutted into different widths with ongitudinal cutting machine. We can also say that the aluminum strip is a deeply processed aluminum product formed by aluminum winding and cutting. It is an important raw material in industry.

The main processing equipment of aluminum strip is the sub-strip unit. According to the annealing state, aluminum strip can be divided into 3 kinds, full soft (o state), half hard (H24 state), full hard (h18 state). At present, the O state should be the popular one, because O state is easier to stretch and bend. Aluminum strip can be used for aluminum plastic composite pipe, cable, optical cable, transformer, heater, shutter, etc.

Aluminum strip can be generally used in utensils, radiators, bottle caps, printing plates, building materials, heat exchanger components, and the deep stamping products. It is widely used in many fields of industrial equipment.

1. The application of aluminum strip is widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries.

2. Aerospace aluminum strip materials are used to produce aircraft skin, fuselage frame, girder, rotor, propeller, fuel tank, wall plate and landing gear pillar, as well as rocket forging ring, spacecraft wall plate, etc.

3. The aluminum strip material for transportation is used for the structural parts of automobiles, subway vehicles, railway buses and high-speed buses, as well as for the doors and windows of automobiles, shelves, automobile engine parts, air conditioners, radiators, automobile body plates, wheel hubs and naval vessels.

4. Packaging aluminum strip materials can be used mainly in the form of sheet and foil as metal packaging materials, cans, covers, bottles, barrels, packaging foil. It is widely used in beverage, food, cosmetic, medicine, cigarette, industrial products packaging.

5. Printing with aluminum strip is mainly used to make PS plate, for aluminum PS plate is a new material in the printing industry, which is used for automatic plate making and printing.

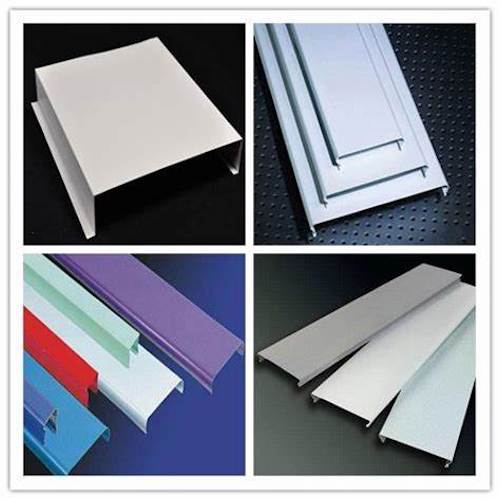

6. Due to its good corrosion resistance, sufficient strength, excellent technical performance and welding performance, aluminum strip coil for architectural decoration is mainly used in building frame, doors and windows, ceiling, decorative surface, and also all kinds of building doors and windows, curtain wall with aluminum profiles, aluminum curtain wall, pressure plate, pattern plate, color coated aluminum plate.

The usage of aluminum strip is also very wide, due to the different processing methods, which brings different use of aluminum strip. It is different from aluminum square and aluminum circle, in the use of aluminum strip, the emphasis is on the use of a tape.

JingleAluminum committed to one-stop solution provider & partner for many different kinds of aluminum materials, including aluminum coil and aluminum sheet, Aluminum foil, aluminum plate, Aluminum sheet, aluminum strip, color coated aluminum coil, embossed aluminum sheet, stucco color coated aluminum sheet, aluminum thread plat, aluminum circle, and so on.